INDUSTRY PROJECT

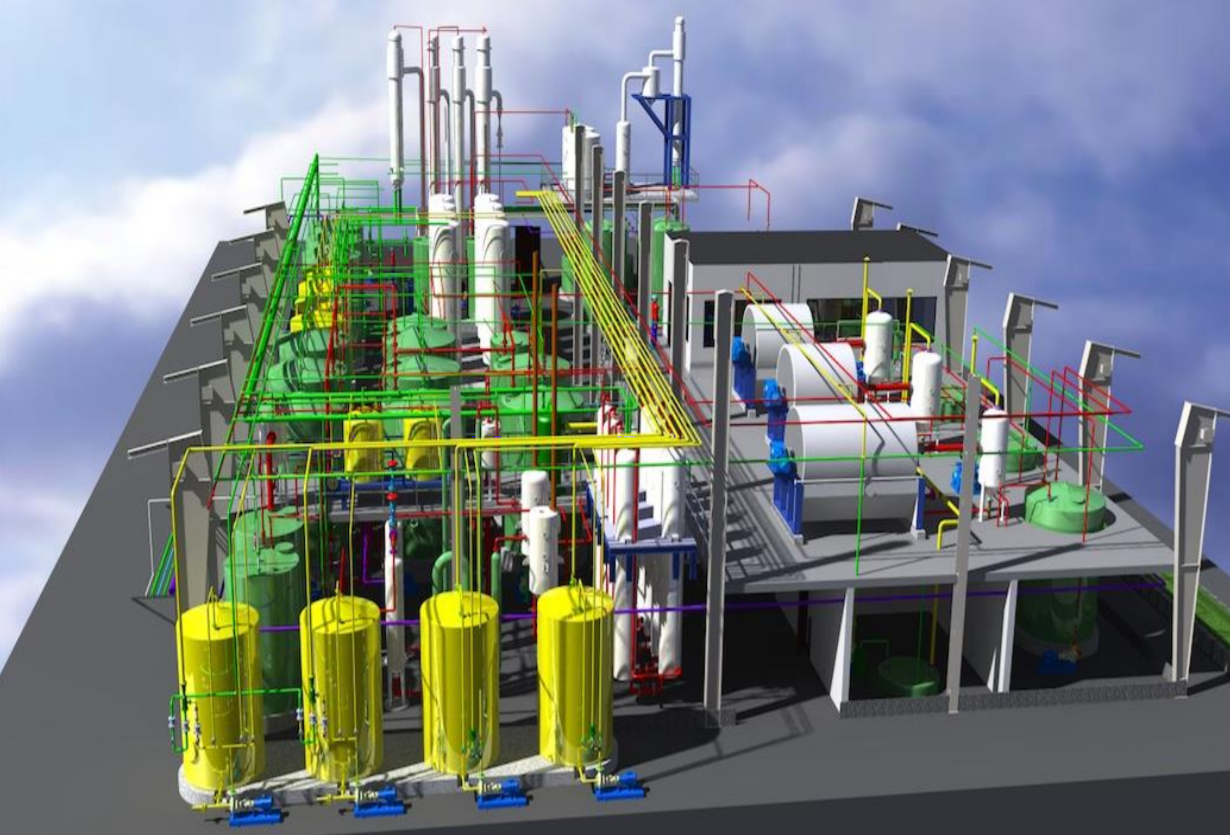

APEX CO., it is a process solution company that can provide comprehensive solutions such as technology, equipment design,manufacturing and timely completion of the project together with solution partners in the field of biorefinery related to renewable energy resources.

APEX CO.; produces complete chemical plants from engineering, procurement and construction to technical and business services. We offer fertilizers, basic chemicals, electrolysis, polymers, gas technology, oil and gas, equipment and technologies for biotechnology and high pressure applications. We work together with our engineering expertise

and experience to produce reliable, efficient and sustainable solutions together with our customers.

APEX CO.; offers first-class spare parts and a wide range of after-sales services for industrial plants and machinery. We provide fast and reliable support for the operation and maintenance of customer premises, as well as support for upgrades, upgrades and spare parts management. We also offer training and consultancy services tailored to the needs of our customers.

APEX CO, Biorefineries, Chemical, Industrial plants, including the design and construction stages, can work effectively in all engineering phases.

APEX CO., is able to meet all processes for designing efficient and sustainable facilities for its customers.

Engineering and Design, Technology Transfer

Concultancy, Project Management

field work

Manufacturing and Installation, Testing

Commissioning, Operating

Training

A-) INDUSTRIAL FOOD FACILITIES

CEREALS AND PULSES STOCKING STEEL SILOS

FLOUR GRINDING FACILITY

PASTRY PRODUCTION FACILITY

FOOD PACKAGING FACILITY

GLUCOSE SYRUP PRODUCTION FACILITY

FRUIT JUICE - BEVERAGE PRODUCTION FACILITY

COLD STORAGE FACILITY

REFINERY OIL PRODUCTION FACILITY

B-) ANIMAL NUTRITION AND PROCESSING FACILITIES

DAIRY CATTLE FARM

BOVINE FARM

BOVINE SLAUGHTERHOUSE AND RED MEAT PROCESSING FACILITY

DAIRY PRODUCTS FACILITY

CHICKEN AND EGG FACILITY

CHICKEN SLAUGHTERHOUSE AND WHITE MEAT PROCESSING FACILITY

A-) FOOD PRODUCTION FACILITIES

1- CEREALS AND PULSES STEEL SILOS

INVESTMENT PURPOSE: It will be possible to bring the wheat, one of the most strategic products of the world, from foreign countries and store it in order to create a safe stock amount for KUWAIT.

By means of other food facilities, products that are to be obtained from buckwheat will be supplied with the domestic market demand and the external dependency will be minimized and safety stock will be created during probable crisis periods.

In this regard, domestic products will be produced and consumed as much as possible within the country of KUWAIT.

2- FLOUR GRINDING FACILITY

INVESTMENT PURPOSE: Since the first priority of APEX is consumer health, stablishment of natural and unadulterated flour production facilities is provided. The main objective of these investments is; it will reduce the foreign loyalty to the minimum for flour which is the basic food material, meeting the region's needs.

Thanks to this project, the plant will produce industrial flour varieties in the first place and will meet the raw material needs of bakery products, biscuit, cake and wafer production facilities. Biscuits, wafer flour, cake and whole wheat flour can be produced in the factory of the establishment provided with the installation.

The capacity of the plant to be built can be increased gradually.

The capacity of the plant to be built can be increased gradually.

Bran, middlings, bonkalite and germ can be produced as side products as well as flour in the plant.

3- PASTA FACTORY

INVESTMENT PURPOSE: To use some of the flour obtained from the flour factory to be used for pasta production and to meet the needs of the country through this facility and therefore to reduce the dependency to the outside.

In the modern facilities we have established as APEX,

pasta is produced in accordance with food safety

processes and monitored continuously with instant

production controls.

A good pasta is produced with good wheat, the right processing process, modern production technology and competence.

4- FOOD PACKAGING FACILITY

INVESTMENT PURPOSE: It is aimed to meet the consumption need by providing pulses of the pulses which are the most important part of KUWAIT people's food consumption materials. For the packaging of pulses and nuts products, the best price and quality from outside of KUWAIT country will be met by supplying pulses and dried nuts in the amount of container.

Pulses Packing: As APEX, we aim to obtain the highest level of

As APEX, we aim to obtain the highest level of

cleanliness with our high efficiency pulses sieving

machines with high efficiency of pulses which is an

important place in the food sector in our packaging

facilities.

5- GLYCOS SYRUP PRODUCTION PLANT INVESTMENT PUSPOSE: In the KUWAIT country, it is aimed to produce glucose syrup for consumption of fruit juices and beverages with high consumption and to meet the need for possible glucose syrup in the countries of the region. The raw material (corn and wheat) needed for the production of glucose syrup will be supplied and supplied at the most appropriate price and best quality in the quantity of the container.

INVESTMENT PUSPOSE: In the KUWAIT country, it is aimed to produce glucose syrup for consumption of fruit juices and beverages with high consumption and to meet the need for possible glucose syrup in the countries of the region. The raw material (corn and wheat) needed for the production of glucose syrup will be supplied and supplied at the most appropriate price and best quality in the quantity of the container.

APEX can offer high efficiency, low cost solutions with technology, equipment design related to glucose syrup production facilities.

6- FRUIT JUICE AND BEVERAGE FACTORY INVESTMENT PURPOSE: Fruits to be used in the plant will be provided both at home and abroad. In the following period, it will be contributed to the development of fruit farming in the KUWAIT state with the need to be covered from the whole country.

INVESTMENT PURPOSE: Fruits to be used in the plant will be provided both at home and abroad. In the following period, it will be contributed to the development of fruit farming in the KUWAIT state with the need to be covered from the whole country.

The sudden feeling of thirst, the need for relief, the dream of eating fresh fruit, the desire to experience pleasant moments and the healthy lifestyle tradition are all represented by fruit juice. As APEX, we ensure that fruit juices, which are indispensable for natural and healthy life, are produced with high quality and safety to be shared with your loved ones every season. APEXis able to offer high efficiency, low cost solutions with technology, equipment design related to fruit

juice production facilities.

7- COLD STORAGE

INVESTMENT PURPOSE: To protect the safety stock of meat, fish, fruit and vegetable needs in the country without deterioration.

In cold conservation, the principle is to ensure that the conditions necessary to allow the lowest possible level of meat, fish, fruit and vegetables to be met with no stopping the metabolic activities.

In cold conservation, the principle is to ensure that the conditions necessary to allow the lowest possible level of meat, fish, fruit and vegetables to be met with no stopping the metabolic activities.

It is very important to determine the correct temperature in the warehouse and use it in terms of the life of the product. As APEX, we aim to provide maximum efficiency and customer satisfaction with our latest technology with high efficiency in our cold storage facilities.

8- REFINERY OIL FACTORY INVESTMENT PURPOSE: It is aimed to reduce the dependency on the outside by providing production in refinery sunflower oil country with high consumption amount in the country. The raw sunflower oil needed as the raw material for the plant will be supplied with the most suitable fiyata and the best quality from the foreign countries and shipments by container. APEX as a turnkey solution for industrial oil and refinery oil plant installations

INVESTMENT PURPOSE: It is aimed to reduce the dependency on the outside by providing production in refinery sunflower oil country with high consumption amount in the country. The raw sunflower oil needed as the raw material for the plant will be supplied with the most suitable fiyata and the best quality from the foreign countries and shipments by container. APEX as a turnkey solution for industrial oil and refinery oil plant installations

B-) ANIMAL FAT AND PROCESSING FACILITIES

Since the whole process from cattle breeding to the processing of animals will be in the country of KUWAIT, the contribution to the country's economy will be minimized by minimizing meat and meat products as well as milk and dairy products.

9-) DAIRY CATTLE FARM With the establishment of 1,000 dairy cattle farms, a part of the poultry needed for the country can be met. APEX provides the installation of the plant by designing all necessary equipments for the milk production to be in the ideal level and healthy

With the establishment of 1,000 dairy cattle farms, a part of the poultry needed for the country can be met. APEX provides the installation of the plant by designing all necessary equipments for the milk production to be in the ideal level and healthy

environment.

10-) BOVINE FARM The establishment of 1,000 bovine farms will ensure that a portion of the country's red meat needs are met. Establishment of fattening cattle farm can be achieved in accordance with the standards required by APEX.

The establishment of 1,000 bovine farms will ensure that a portion of the country's red meat needs are met. Establishment of fattening cattle farm can be achieved in accordance with the standards required by APEX.

11-) BOVINE SLAUGHTERHOUSE AND RED MEAT PROCESSING FACILITY Slaughterhouse will be provided in accordance with international standards and hygiene rules in the area to be installed by APEX. After slaughtering, the same meat processing can be done according to desired meat products.

Slaughterhouse will be provided in accordance with international standards and hygiene rules in the area to be installed by APEX. After slaughtering, the same meat processing can be done according to desired meat products.

12-) DAIRY PRODUCTS FACILITY

INVESTMENT PURPOSE: Hundreds of tons of fresh and natural milk every day is aimed to meet the needs of the people of KUWAIT by providing the conversion of pasteurized milk to yoghurt, ayran, cheese and butter with the addition of no additive material without harming the nature. With this facility, a portion of the milk and milk products in the country will be provided.

13-) CHICKEN AND EGG FACILITY

Feeding Chickens In poultry farming, success is due to genetic characteristics as well as good care and feeding. No matter how high the yield of the animal is, the expected yield is not reached as long as the conditions of care and feeding are not appropriate. Nutrition is extremely important both in terms of quality of the egg.

The most important part of chicken breeding is feed. For a profitable poultry, both economical and adequate feeding is necessary. The quality of the ovaries is influential and influences the egg significantly. Therefore, care should be taken to ensure that the food is a reliable brand, that the content of the oath and the gender are indicated on the bag. We use automatic feeding system in our farm.

Collection of Eggs With the automatic egg collection system, probable fractures in the egg are collected by minimizing it. The bands used in the egg collection system are synthetic and egg plastic tape holders are used to prevent their sagging. The tapes used are often woven and synthetic, allowing the eggs to remain clean and have a food production certificate.

With the automatic egg collection system, probable fractures in the egg are collected by minimizing it. The bands used in the egg collection system are synthetic and egg plastic tape holders are used to prevent their sagging. The tapes used are often woven and synthetic, allowing the eggs to remain clean and have a food production certificate.

Egg collection process; each kata is made easier and faster thanks to the special gearmotors. It is a border switcher at the conveyor outlet and easily adapts to egg coding and sorting systems. The system has been manufactured to allow the egg to move easily to the desired sorting chambers.

Packaging After the eggs are collected, they need to be packaged for sale. We use automatic packaging system while packaging the eggs. We are also considering how to pack eggs when preparing our business plan. We comply with all laws and regulations when packing and selling eggs.

After the eggs are collected, they need to be packaged for sale. We use automatic packaging system while packaging the eggs. We are also considering how to pack eggs when preparing our business plan. We comply with all laws and regulations when packing and selling eggs.

APEXis able to offer comprehensive solutions such as equipment design with high technology, high efficiency, etc., in the chicken farms where the installation is done, and the project can be completed in ideal conditions.

14-) CHICKEN SLAUGHTERHOUSE AND WHITE MEAT PROCESSING FACILITY

As APEX; We are establishing Tavuk Slaughterhouse Facilities which has been developing continuously since its existence, always performing the firsts in the developing sector and having the latest technology in the world. In this system, the chicks are softened using condensed air instead of water. Thanks to this system; hygienic production of the products in natural color, natural flavor and natural smell is provided.

APEX is also securing white meat products with its 4-stage hygiene bar in the production process. At the same time we contribute to the conservation of nature through the large-scale water and electricity savings provided in production. Thanks to the state-of-the-art technology used in the plant installation, up to 75% of chicken production and 60% of water consumption is achieved. Water consumption is kept at the lowest level

by using enriched air in more hygienic conditions instead of water consumption in 2 important stages of production.

APEX, white meat industry technology, equipment design, manufacturing, and the completion of a project in

time.